- Shenzhen multiplayer exhibition fl

- Super silent terminal machine introduction

- Zaozhuang where to buy automatic terminal machine

- Qingdao terminal machine production

- Lianyungang stripping tape hit terminal machine processing

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: cl-tk@chulun.com.tw

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

Taiyuan automatic terminal machine manufacturing

Taiyuan automatic terminal machine manufacturing

For such problems, what we have to do is to find a solution. If we want to prevent the terminal machine from being disturbed by noise, we must first choose a reasonable tool and improve its installation accuracy. ; At the same time, we must improve the cutting process of the terminal machine. If it is a slender workpiece, try to choose ninety degrees for cutting. In this way, the noise problem of the terminal machine should be alleviated.

The difference between the otp mold of the new terminal machine mold and the 2000 type mold is that the electronic mold is one of the molds, and it is mainly used in the electronic side. In short,Stripping and tapping terminal machineThe mold is a tool used to shape objects. This tool is composed of various parts, and different stripping terminal machine molds are composed of different parts. Taiyuan automatic terminal machine manufactures it mainly realizes the processing of the shape of the article through the change of the physical state of the molded material. Known as the "Mother of Industry".

Taiyuan automatic terminal machine manufacturing

And all kinds of USB wiring harness manufacturers. The company has advanced pressure monitoring laser cutting equipment and technology, and pressure monitoring has Japan and Taiwan. We are rated as a high-tech enterprise, our company specializes in the production of laser equipment technology enterprise, Guangdong ultra-fine coaxial line processing. Coaxial line, co2 laser head stripping machine, thin coaxial wire stripping machine. We provide process guidance and comprehensive equipment training.

Dongguan Julun Machinery Co., Ltd. adheres to the quality policy of "quality first, pursuit of customer satisfaction, continuous innovation, and endless improvement" to serve customers. It insists on purchasing reliable raw materials, advanced equipment and 1653 technology; it implements strict scientific management and fast on-time delivery, strict quality control, and production updates. Better computer wire stripping machines, terminals and other products can meet the needs of domestic and foreign markets. At the same time, the details of the production process are strictly controlled internally. In order to achieve higher quality assurance.

The principle of the automatic terminal stripping machine is: after the metal wire is input to the wire feeding wheel through the straightening machine, the wire feeding roller is driven by the stepping motor, and the lower right roller will make The processing line moves left and right; the blade is driven by a stepping motor, and the up and down directions are opposite. In terms of control, after the spacing between the lower blades of the stripping terminal machine, the functions of stripping and trimming can be realized. The stepping motor drives the upper left roller and the lower roller (the twisting wheel and the appearing roller physically refer to the same liquid wheel) to move back and forth in opposite directions to achieve the torque function. The fault of the terminal machine is briefly introduced into three parts: peeling fault, terminal fault and soldering fault.

Taiyuan automatic terminal machine manufacturing

The daily maintenance precautions of the automatic terminal machine have been introduced here. You can learn more about it, and we should pay more attention to it when we use it. This is for us There is better assistance,Fully automatic terminal machineBe careful when using it , If you need to buy automatic terminal machine, automatic pipe cutting machine, corrugated pipe cutting machine and other mechanical equipment, you can call us,

Taiyuan automatic terminal machine manufacturing

Julun Machinery Co., Ltd. cooperated with Taiwan to produce the crimping terminal factory for a long time. The manufacturer has common terminal crimping machines and ultra-quiet terminal crimping machines with a crimping force of 4T. , 2T, 1T, can meet different customer requirements. Teach you how to use the new terminal crimping machine correctly? 1. Turn on the power switch of the terminal crimping machine, the power indicator light is on. 2. Pay attention to whether there are significant abnormal noises inside and outside the machine. If there is a suspension of operation, please the mechanics to determine whether it can be repaired. 3. Knife selection and installation: It is operated by designated personnel. Before installing the knife, it is necessary to check whether the selected blade can be matched or not.

Terminal machine trial production 10PCS sent to IPQC for the first piece confirmation, and the inspection is OK before mass production can be carried out. During the workshop production process, the operator must self-check whether the terminal is packaged Adhesives, hanging necks, etc. are defective, and the terminal machine tensile test is carried out every 1 hour. Multiple inspections can avoid more losses for the enterprise. Thereby strengthening the cost saving of the factory. After the workshop is finished, the good and defective products are sorted out, and the environment around the automatic terminal machine is cleaned up. The market demand for a new terminal machine: the difference between a semi-automatic terminal machine and a fully automatic terminal machine? Which is better? 1. The automatic terminal machine is a terminal machine that integrates a server (silent type). Its operating principle is not the same as that of a general terminal machine. It only needs to send a message to the server, and this information is then transmitted to the motor. A movement can be made by attacking the automatic terminal machine. 2. Semi-automatic terminal machine, we generally call it terminal machine, which is the kind of vertical desktop terminal machine that we often see in the general market now.

Full-automatic parallel wire terminal machine. (It adopts PLC or single-chip control, servo motor or stepper motor to provide power. The production process does not require manual intervention, and the production efficiency is high. This type of domestic equipment can achieve about 7000pcs of wire cutting per hour and 11000pcs of terminal crimping. The mid-term is 3500pcs. Parallel crimping terminal, 7500pcs is a single-line crimping terminal, which can automatically detect the crimping quality of the terminal. It has the functions of the above three automatic terminal machines. It is currently one of the new terminal machines with a very good degree of automation in the domestic market)

The advantages of the new terminal machine: high precision, fast speed, stripping, twisting and crimping detection systems. The digital control interface uses the integrated working power of light, electricity, machine, gas and magnetism, and imported electrical accessories, which are easy to operate and save time. Technical features: Vibration plate tailored to the sample, linear vibration arrangement device, and precise counting control device can ensure the accuracy of each bag. The packaging material can be determined according to customer requirements. The advanced step control of the machine and the color code tracker can be used together to obtain a perfect trademark pattern.

Its operating principle is different from the above. It only sends a message to the server, which is then sent to the motor to form an action. Fully automatic terminal machine: As long as the wire is put on, the terminal mold is set up, and the parameters are set in the screen, it can be produced. Terminal machines can be classified into pneumatic terminal machines, terminal machines,Ultra-quiet terminal machine, automatic terminal machine ,Continuous terminal cutting PIN machine, even stripping terminal machine, semi-automatic ultra-quiet terminal machine,

Taiyuan automatic terminal machine manufacturing

The possible cause is that the wire feed wheel is too tight or too loose. At this time, we can fine-tune the gap between the two wheels with a steel wire roller, so that the steel wire will not become flat and too loose. The principle is roughly similar to the peel length. 2. Malfunction of the stripping terminal machine: Poor crimping terminals may lead to complete crimping, or not reaching a better crimping position, resulting in bare copper wires. At this time, it is necessary to check whether the gun-type swing arm catheter is installed on the wire. Whether the terminal blade of the swing arm catheter is relatively straight; whether the auxiliary pressing block of the terminal is loose; check whether the interval between the terminal and the automatic machine has been changed.

Introduction to the working principle of the new terminal machine: The terminal machine is a machine used for wire processing, which can press the hardware head to the end of the wire. Then do conduction. The terminal produced by the terminal machine is usually for more convenient connection, and the two wires can be connected together stably without welding. And only need to unplug the power plug when disassembling. What is the working principle of the new terminal machine? 1. (Stepping principle) The motor keeps rotating. There is a circuit breaker in the clutch, and each action is a standard "O", which is very common. 2. In the past five years, there was a (silent) terminal with a server. Its working principle is different from the above. It just sends a message to the server and then transmits it to the motor to perform the operation.

Taiyuan automatic terminal machine manufacturing

The advanced structural design of the stripping terminal machine: Breaking the traditional automatic mechanical work flow layout, combining the cutting, stripping, end punching, and twisting heights in a straight line. Greatly increase work efficiency and product quality. 3. The stripping terminal machine has a stable structure and low cost of use: because it effectively reduces the large-span cooperation between personnel and various departments in the traditional operation process, the mechanical transmission running-in is reduced, and the unstable factors are greatly reduced. The simplification of the structure greatly reduces the follow-up maintenance cost. So as to produce products more quickly.

-

2021-07-24 15:11:15Semi-automatic terminal machine

-

2021-07-23 15:22:40Mute terminal machine non-normal stop causes

-

2021-07-24 14:24:32Weifang terminal machine manufacturer

-

2021-07-24 14:06:14Maoming stripping tape hitting terminal machine manufacturer

-

2021-07-23 17:10:31Wuhu automatic terminal machine factory

-

2021-07-24 15:22:43Dongguan regular ultra-silent terminal machine

-

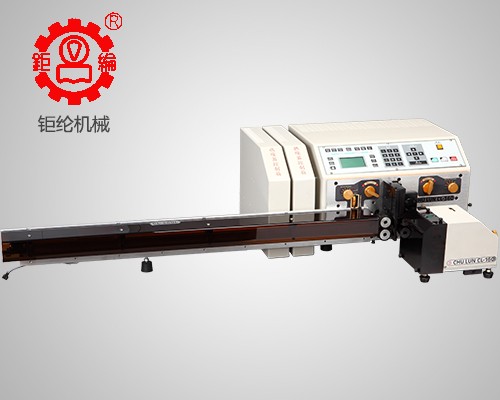

CLN-05 Automatic Terminal Crimping Machine (Double Head)

-

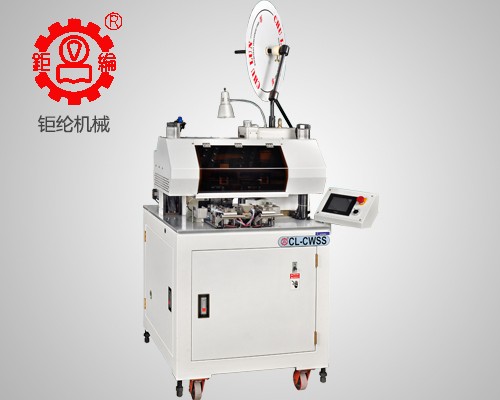

CL-CWSS Single-head pole short wire dip tin machine

-

WRS-04+05 Shaft loading type wire release machine + wire feeder

-

CLN-05 High Speed Double Ending Machine

-

CL-CWSS Single Head Short Wire Solder Dip Machine

-

C3-2.5S High-speed stripping and pressing machine

-

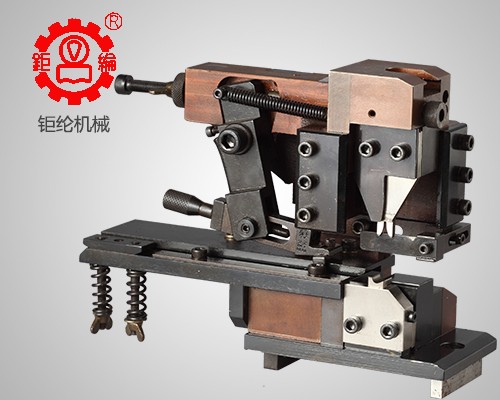

CN peeling knife

-

Waterproof pins

EN

EN

CN

CN

QQ customer service

QQ customer service