- Ningbo automatic terminal machine brand

- Texas domestic automatic terminal machine

- Silent terminal machine non-normal stop causes

- Semi-automatic terminal machine

- Silent terminal machine in the operation of some small failures and the corresponding countermeasures may occur

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: cl-tk@chulun.com.tw

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

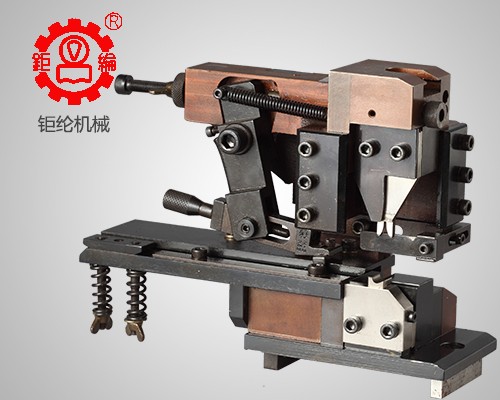

Introduce the use of stripping tape hitting terminal machine specifications

Striping and tapping machine The impact strength is very large, so you should be careful when operating, and the stripping and tapping machine is correct The operation process is as follows:

1. Turn on the power switch of the terminal machine, and the power indicator light is on.

2. Pay attention to whether there are significant abnormal noises inside and outside the machine. If there is a suspension of work, please ask the mechanic to determine whether it needs to be repaired.

3. Knife selection and installation: It is operated by designated personnel. It is necessary to manually compare whether the selected blade is matched before installing the knife. After the comparison is correct, the knife can be installed and the installation is completed. After that, it is necessary to use the hand-cranked test. First, turn off the power of the terminal machine, press the adjustment button, and use a special wrench to swing the master and follower wheels to maximize the stamping stroke of the stripping terminal machine. If the hand does not move, consider whether it is under pressure Excessive size or other problems, check and debug to OK. Before operation, check each locking screw and confirm that there is no looseness.

4. Loading: Install the terminals that need to be punched, use the hexagonal wrench to adjust the feed pressure plate, so that the terminals can pass through easily, visually check whether the feeding direction is suitable, if not, For conditioning, use an inner hexagon wrench to loosen the feeder locking screw, turn the conditioning rod to adjust until it is in the state, then tighten the feeder locking screw, and start the operation.

5. Test tension: After adjusting the machine OK, take the scrap wire and test it for a tension test. The main reference values are shown in the "Rally Test Comparison Table". The specific operation method is as follows, press The tension test reset button is adjusted to zero, the terminal wire to be tested is clamped, and the test is carried out. If the measured tension is not within the specified range, the mechanic should adjust it from the beginning until the specified value is reached.

6. The trial production of 10PCS will be sent to IPQC for the first piece approval, and the inspection is OK, then mass production can be carried out. During the production process, the operator must self-check whether the terminals are glued or not , Hanging neck and other defects, and conduct a terminal tension test every 1 hour.

7. After the production is completed, arrange the good and waste products, and clean the environment around the stripper and terminal machine.

-

2021-07-24 14:29:16Silent terminal machine inspection method

-

2021-07-24 15:27:22Jining stock intelligent terminal machine

-

2021-07-24 15:58:23Xianyang small semi-automatic terminal machine

-

2021-07-23 15:21:28Silent terminal machine non-normal stop causes

-

2021-07-23 15:23:06Automatic terminal machine history and future?

-

2021-07-24 15:34:07Maoming automatic stripping tape hitting terminal machine

-

WRS-07 Multifunctional Wire Feeder

-

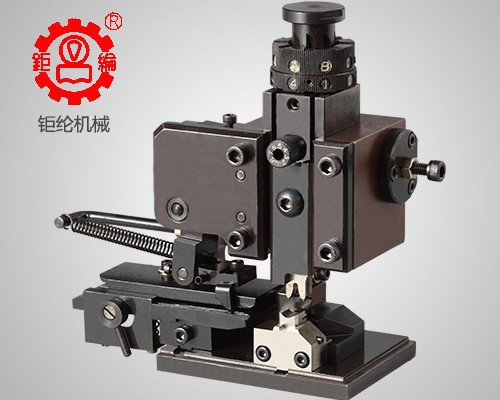

CLN-05 Automatic Terminal Crimping Machine (Double Head)

-

WRS-04+05 Shaft loading type wire release machine + wire feeder

-

CLM-2S card module

-

CLS-1T Copper Strip Machine

-

CLM-3W Card Module

-

CLN-05-CH Automatic Automatic Termination Solder Dipping Machine

-

CL-CWSS Single Head Short Wire Solder Dip Machine

EN

EN

CN

CN

QQ customer service

QQ customer service