- Wire cutting machine

- Lianyungang stripping tape hit terminal machine processing

- Huzhou automatic terminal machine processing factory

- Erdos terminal machine for sale

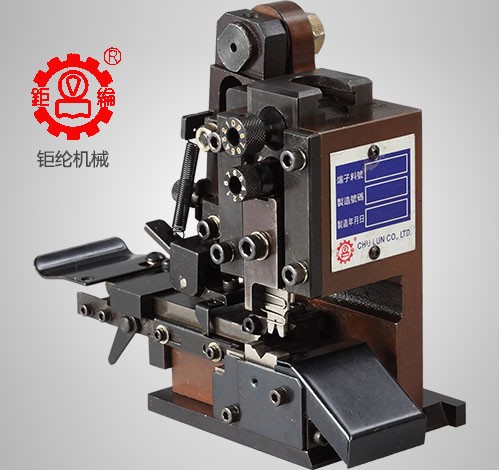

- Semi-automatic terminal machine

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: cl-tk@chulun.com.tw

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

Suqian professional manufacturing computer wire cutting machine

Suqian specializes in manufacturing computerized wire cutting machines

Fully automatic terminal machineIt is still a kind of mechanical product that is used more in our lives. It should be understood! Also, because this kind of product is fully automatic, the hours and minutes used are much more convenient, and the work efficiency can be improved a lot, but no matter what it is, we must learn to maintain it when we use it. If it is well maintained, then we use it. It can also extend its use time when it gets up, but what should we pay attention to when we enter the field for maintenance?

Suqian specializes in manufacturing computerized wire cutting machine. Computerized wire cutting machine safe operation rules: 1. When the ultra-quiet terminal machine is adjusted and the paper cutter is changed, the machine must be shut down. Even when the machine is stopped, it is strictly forbidden to put your hands under the knife to change the knife. Long-handled bolts and other tools should be used to change the knife. They must be removed during the test run to avoid injury to the operator when the machine is started. 2. The power supply must be blocked when the ultra-quiet terminal machine machine adjusts, exchanges blades, and repairs, refuels, scrubs and inspects. Dongguan Julun Machinery Co., Ltd. welcomes new and old customers to come to negotiate.

Suqian specializes in manufacturing computerized wire cutting machines

Automatic terminal machine maintenance precautions

1. It is necessary for the staff to clean the machine every day to remove the dust, debris and remaining oil on the surface of the machine.

Full-automatic parallel wire terminal machine. Controlled by plc or single-chip microcomputer, ultra-quiet terminal machine servo motor or stepping motor provides power. The production process does not require manual intervention, and the production efficiency is high. This type of domestic equipment can achieve about 7000pcs of wire cutting per hour and 11000pcs of terminal crimping. In the mid-term, 3500pcs are parallel crimping terminals and 7500pcs are single-line crimping terminals, which can automatically detect the crimping quality of the terminals. It has the functions of the above three automatic terminal machines and is currently one of the most highly automated terminal machines in the domestic market.

2. The crimping part of the automatic terminal machine must be added with butter every week, and evenly spread on the surface of the high-speed bearing and around the press block.

Terminal machine debugging is mainly mold debugging, and this part of the mold is divided into feeding and blade debugging. Generally speaking, there are 4 blades for terminal machine blades, and there are 2 upper blades and 2 lower blades. There are 2 blades, the upper blade is divided into the inner blade and the outer blade, and the lower blade is the same. You understand these next steps of debuggingUltra-quiet terminal machineIt’s a lot easier. You must manually debug the ultra-quiet terminal machine. One is safe, and we can see if the crimped terminal meets the requirements in manual debugging. The bonding grid mainly depends on the part of the crimping copper wire, because it is conductive, so the key is too tight, it will crush the copper wire or directly break the blade, and the terminal and the wire will easily fall off if it is loose.

Ultra-quiet terminal machine, what is the reason why Julon’s ultra-quiet terminal machine always keeps hitting? The terminal machine often keeps hitting. It may be the terminal machine, the terminal board or the inverter If it is broken, you still need to find professional personnel to repair it. Dongguan Bochi Automation Equipment Co., Ltd. specializes in the production of wire harness processing equipment. The main products are: automatic terminal crimping machine (single-head/double-head/dip tin), computer wire cutting Wire stripping and twisting machine, silent terminal crimping machine, high-speed silent high-speed terminal machine with stripping and twisting, terminal machine molds, blades and mechanical accessories and other wire harness processing equipment.

Suqian specializes in manufacturing computerized wire cutting machines

3. It is necessary to add oil to the stamping guide rail of the automatic terminal machine once an hour. The smooth oiling hole is on the top of the terminal machine. It is advisable to use 2-3 drops each time. .

Full-automatic parallel wire terminal machine. Controlled by plc or single-chip microcomputer, ultra-quiet terminal machine servo motor or stepping motor provides power. The production process does not require manual intervention, and the production efficiency is high. This type of domestic equipment can achieve about 7000pcs of wire cutting per hour and 11000pcs of terminal crimping. In the mid-term, 3500pcs are parallel crimping terminals and 7500pcs are single-line crimping terminals, which can automatically detect the crimping quality of the terminals. It has the functions of the above three automatic terminal machines and is currently one of the most highly automated terminal machines in the domestic market.

The daily maintenance precautions of the automatic terminal machine have been introduced here. You can learn more about it, and we should pay more attention to it when we use it. We have better assistance. We should be more careful when using the automatic terminal machine. If you need to buy automatic terminal machines, automatic pipe cutting machines, corrugated pipe cutting machines and other mechanical equipment. Contact us by phone, and we also have punctured terminals, terminal molds, terminal copper strips and other accessories. If you need them, please contact us by phone.

Suqian specializes in manufacturing computerized wire cutting machine. Computerized wire cutting machine safe operation rules: 1. When the ultra-quiet terminal machine is adjusted and the paper cutter is changed, the machine must be shut down. Even when the machine is stopped, it is strictly forbidden to put your hands under the knife to change the knife. Long-handled bolts and other tools should be used to change the knife. They must be removed during the test run to avoid injury to the operator when the machine is started. 2. The power supply must be blocked when the ultra-quiet terminal machine machine adjusts, exchanges blades, and repairs, refuels, scrubs and inspects. Dongguan Julun Machinery Co., Ltd. welcomes new and old customers to come to negotiate.

Suqian specializes in manufacturing computerized wire cutting machines

Suqian specializes in manufacturing computerized wire cutting machines

How many square lines should be used and how many tonnage terminal machines, terminal machines can be classified as fully automatic terminal machines, connectingStripping and crimping machine , ultra-quiet terminal machine, pneumatic terminal machine, terminal Wire terminal machine, etc. The automatic terminal machine can be divided into: 1. Automatic single-head crimping terminal machine (using PLC or single-chip control, this type of domestic equipment can realize about 5000pcs wire cutting, stripping, single-end crimping terminal per hour, and automatic Detecting the quality of terminal crimping, which is more popular in the domestic market

-

2021-07-24 15:22:43Dongguan regular ultra-silent terminal machine

-

2021-07-24 14:43:38Intelligent terminal machine

-

2021-07-23 16:43:10Erdos terminal machine for sale

-

2021-07-23 16:46:05Huzhou terminal machine cost

-

2021-07-23 15:21:28Silent terminal machine non-normal stop causes

-

2021-07-23 17:07:42Original automatic terminal machine manufacturers

-

C2-1.2 terminal machine

-

CL-PPM-V1 Straight type pneumatic stripping machine

-

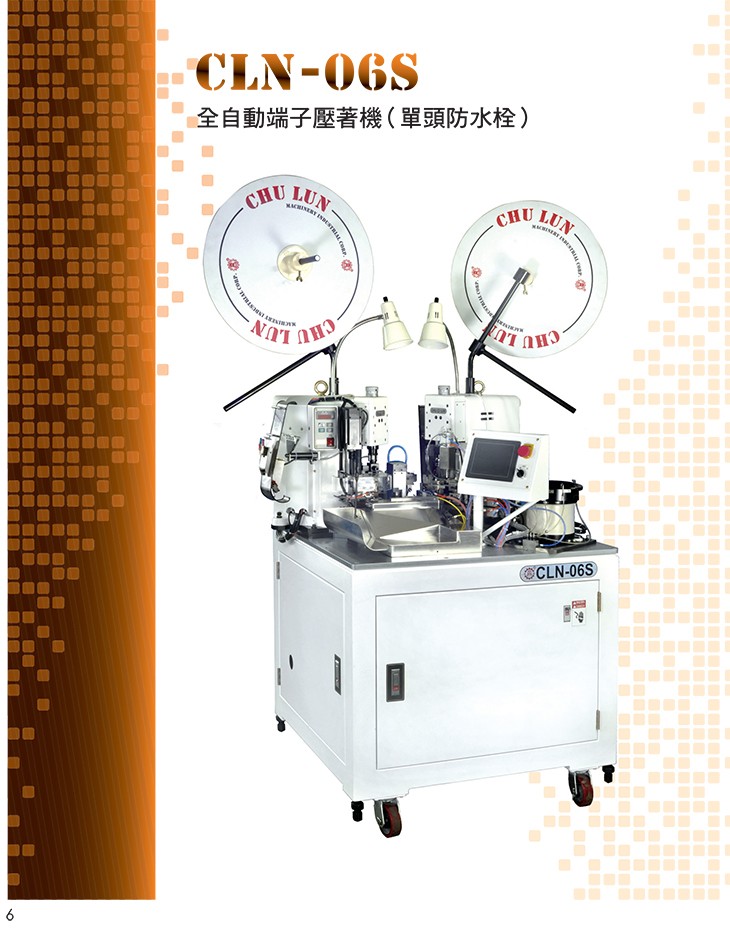

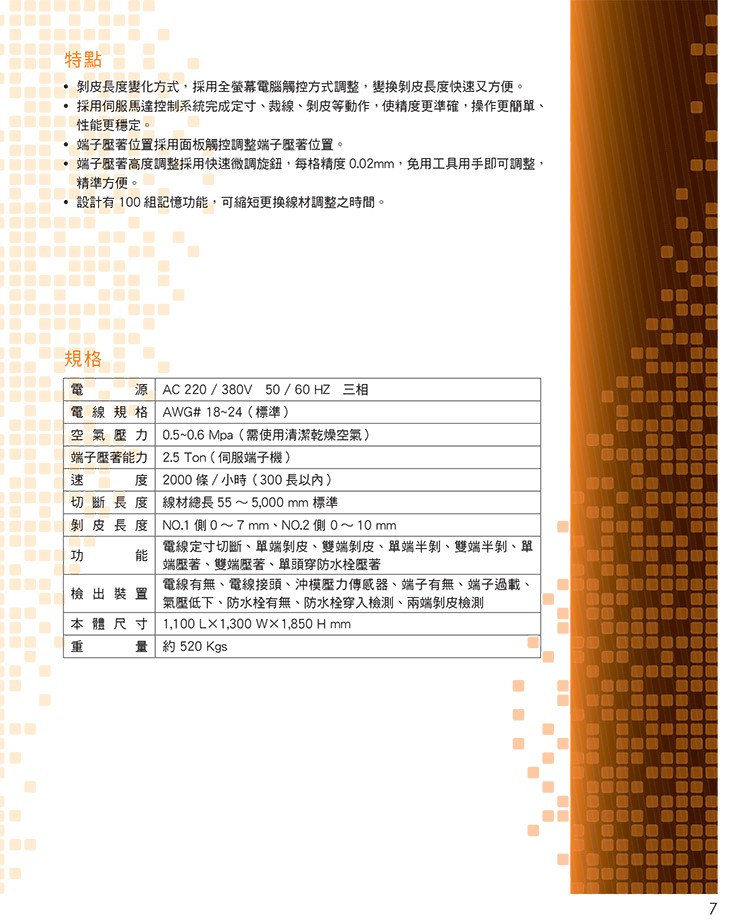

CL-RSS Automatic Terminal Crimping Machine (Single Head Thin Wire)

-

CL-CWSS Single Head Short Wire Solder Dip Machine

-

CN peeling knife

-

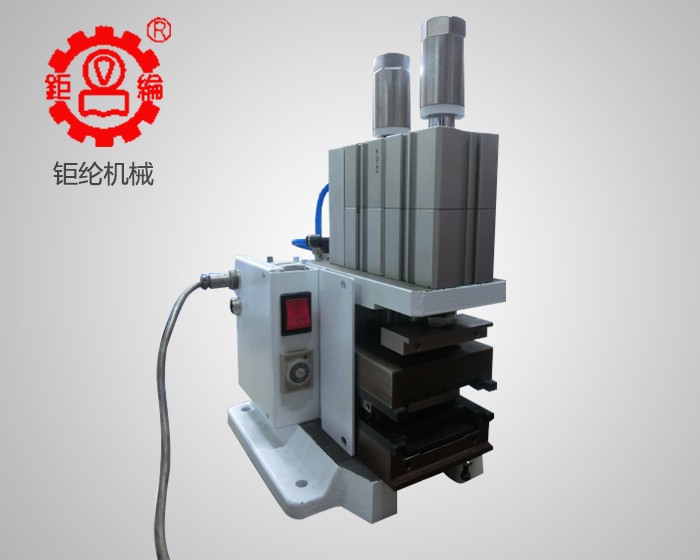

CLM-4S mode card die holder

-

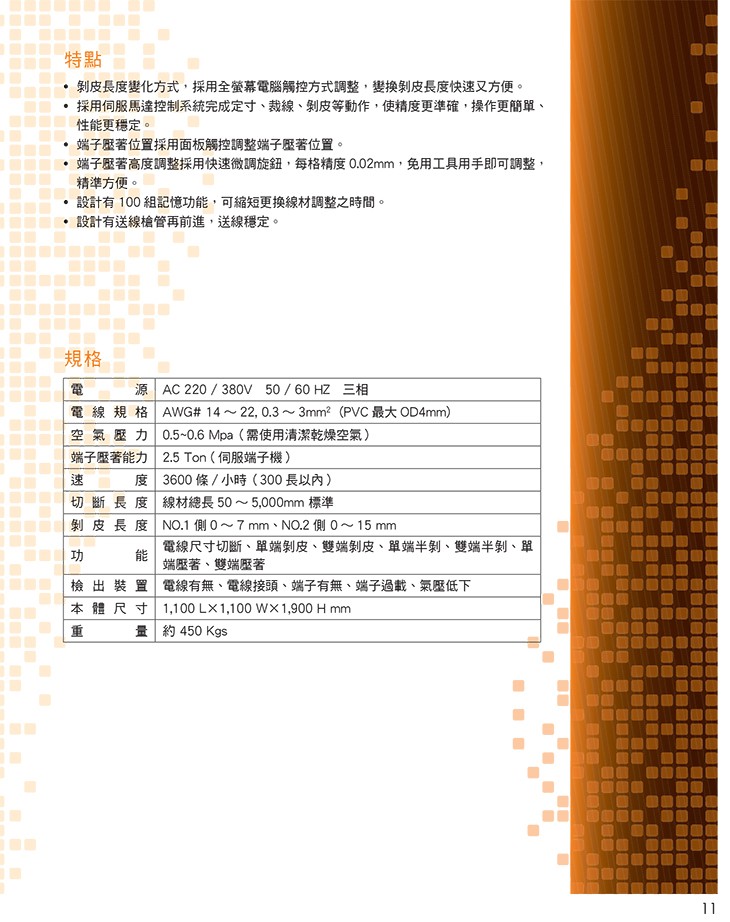

CL-950N Super Speed Automatic Computerized Wire Cutting Machine

-

CL-540+170 Automatic Computerized Wire Cutting Machine

EN

EN

CN

CN

QQ customer service

QQ customer service