- Zaozhuang where to buy automatic terminal machine

- Tangshan where to peel the tape hitting terminal machine

- Dongguan regular ultra-silent terminal machine

- Erdos terminal machine for sale

- Texas domestic automatic terminal machine

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: cl-tk@chulun.com.tw

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

Original automatic terminal machine manufacturers

Original automatic terminal machine manufacturer

The ultra-high-speed silent peeling and tapping machine in the workshop is a fixed asset. The use date is March 2012, and the life span is 10 years. Its original value is 18,000 yuan. It is a general enterprise production equipment. /span>Strip terminal machineThe straight-line method is used to accrue depreciation, and the monthly depreciation amount=18000*(1- 3%)/10/12=145.50. The use date is from March 2012 to July 2013, which is 9+7=16 months, and the depreciation amount in July 2013=145.5*16=2328 yuan.

Automatic terminal machine: As long as the wire is worn, the terminal mold is set up, and the parameters are set in the screen, Can be produced. Terminal machines can be classified into pneumatic terminal machines, terminal machines, ultra-quiet terminal machines, automatic terminal machines, continuous terminal cutting PIN machines, continuous stripping terminal machines, semi-automatic ultra-quiet terminal machines, wire stripping terminal machines, and terminal blocks Machine, stripping machine, small diamond terminal machine, series motor stator terminal machine, computer wire automatic stripping machine, pin terminal machine, gold wire terminal machine, etc. The step angle of my stepping motor is 1.2 degrees, and the motor rotates a circle to drive the axis to move at a distance of 200mm. Now I am subdividing the drive to 1000 steps/revolution. Now the actual movement distance of the motor is 300mm. How many pulses do I need? Can it be moved to 300mm? Ask a master to help in the calculation, how to calculate it.

Professional manufacture of terminal crimping machines, what are the disadvantages of high-speed terminal crimping machines: 1. The damage rate of terminal materials has been improved. 2. The product is scrapped due to equipment adjustment. Intelligent terminal crimping machine and ultra-quiet terminal machine are better to use. The ultra-quiet terminal machine is a bit cheaper, but there is no intelligent professional manufacturing terminal machine that is easy to use. You can use whichever is easy to try first. Dongguan Julun terminal machine is not bad, our company uses their factory, the service is ok, on call.

Continuous stripping terminal machine: The continuous stripping terminal machine belongs to the semi-active model. It has the function of active peeling and crimping terminals. After manual feeding, the foot pedal power switch is controlled to complete the operation. The output power is relatively high. The machine has the functions of active peeling and crimping. During the operation, manual feeding is required, and the pedal method is required, and the production power is high. The quotation is cheaper than the quotation of all active terminal machines.

The stripping and tapping machine is a semi-automatic type. As the name suggests, it has the functions of automatic peeling and crimping of the terminals, but it requires manual feeding and manual control of the foot power switch to work. The production efficiency is high and the price is low. 3. Ultra-quiet terminal machine, professionally manufactured terminal machine with server (frequency converter), belongs to the semi-automatic model, needs manual feeding and manual control of the foot pedal power switch to work. The working principle is similar to the stripping terminal machine, but it does not have the automatic thinning function (usually used in conjunction with the computer wire cutting machine), low energy consumption and low price.

Safety inspection of Dongguan Julun automatic terminal machine before operation: confirm that the wrench has been removed. Tighten the round nut after adjustment. Press the operation switch of the terminal machine to the working position, and the motor starts to run. Place the wire in the proper position of the crimping part of the terminal (the crimped terminal must be in the middle of the upper and lower die cutters). Step on the foot switch, the main unit slides down, complete the crimping of the wire and the terminal, and send the next terminal to the crimping position. Repeat the above steps to achieve continuous crimping between the wire and the terminal.

Original automatic terminal machine manufacturer

The stripper and terminal machine must be shut down when adjusting and replacing the paper cutter. Even when the machine is stopped, it is strictly forbidden to put your hands under the knife to change the knife. Long-handled bolts and other tools should be used to change the knife. They must be removed during the test run to avoid injury to the operator when the machine is started. 2. The power supply must be blocked when the stripping terminal machine is adjusted, the blade is exchanged, and when repairing, refueling, scrubbing and inspection.

Original automatic terminal machine manufacturer

The terminal machine checks whether the moving parts are normal. 5. When the mold is placed, a glue stick or cloth piece should be put on the knife edge to protect the tool. 6. Whether the marking is clear and can be one-to-one correspondence. 7. For receiving and issuing, the "Mold Entry and Exit Account Record Form" must be completed and completed. All of the above can be written into the "Homework Instructions", remember to include pictures. This is called perfection. Specializing in manufacturing the difference between the otp mold of the terminal machine and the 2000 type mold. Electronic mold is a kind of mold, mainly used in the electronic side. In short, a mold is a tool used to shape objects. This tool is composed of various parts, and different molds are composed of different parts.

Turn on the power switch of the automatic terminal, and the power indicator light is on. Pay attention to whether there are obvious abnormal noises inside and outside the machine. If the operation is suspended, ask the maintenance personnel to determine whether maintenance is required. Knife selection and installation: operated by designated personnel. Before installing the tool, you need to manually compare whether the selected tool matches. The tool can only be installed after the comparison is correct. After installing the tool, it must be tested manually.

After the original automatic terminal machine manufacturer has finished processing a line, paste a label on the rubber cone, and be sure to indicate the model of the terminal machine used for the line, the specifications of the line and For the processing of the same number of wires, the original automatic terminal machine manufacturer should re-check to confirm the opening and stripping length of the terminal machine and whether the opening effect is qualified after the equipment has been continuously operated for 1 hour. You can try the operation method of mechanical professional manufacturing terminal machine. Introduction to the five installation steps of the automatic terminal machine.

Professional manufacturing of terminal machines and wire harness processing equipment. The whole country is a fully automatic terminal crimping machine. Terminal machine. Wire cutting machine. Cassette mode. The blade waits for someone to do better. Dongguan Julun Machinery Co., Ltd. is committed to the research, development, manufacturing and sales of automatic wire processing machinery and equipment. The product range includes full-automatic single-head terminal machine, full-automatic double-head terminal machine, continuous stripping and tapping machine,Ultra-quiet terminal machine, computer wire stripping machine, high-speed wire cutting machine, pipe cutting machine, tying machine, etc. Products are exported to Southeast Asia, Europe and the United States. Sincerely welcome new and old customers to come to discuss cooperation.

Original automatic terminal machine manufacturer

First, turn off the power of the automatic terminal machine, press the down touch button, and use the special board to manually move the master and slave wheels to greatly increase the original imported terminal pressure The punching stroke of the machine. If the hand does not move, consider whether the pressure is too high or there are other problems, check and adjust to normal. Before operation, check and confirm that the locking screws are not loose.

Original automatic terminal machine manufacturer

The development of professional manufacturing terminal machine: how to install the automatic terminal machine? Put the qualified terminals on the professionally manufactured terminal rack according to the requirements, and install the terminal chain head into the equipment according to the correct method. Confirm that the die of the equipment matches the installed terminal, then adjust the pressure and other parameters of the equipment, and adjust the corresponding position of the terminal chain and the equipment. Take the stripped wire and check for defects, then align the wire with the slot of the terminal machine and put it in the terminal opening, adjust the position, and then step on the pedal with your foot.

Original automatic terminal machine manufacturer

Adjustment of the closing height (crimping height) of the Julon automatic terminal machine: When the closing height of the terminal machine is not suitable or the adjustment of the mold crimping height micro-adjuster plate is insufficient, It can be achieved by adjusting the adjustment joint and loosening the round nut. Insert the adjusting rod into the round hole on the adjusting joint and turn it. Turning left will decrease the pressing height, and turning right will increase the pressing height (the engraved line on the adjusting joint is 0.1mm per grid, and one turn is 3mm). From high to low, adjust to the proper compression of the wires and terminals. It should not be too tight. Too tight will easily damage the upper and lower die blades.

-

2021-07-24 14:50:33Terminal machine

-

2021-07-23 17:07:42Original automatic terminal machine manufacturers

-

2021-07-24 15:38:30Suqian professional manufacturing computer wire cutting machine

-

2021-07-23 15:22:10How to effectively reduce the danger of operating the terminal machine?

-

2021-07-24 15:58:23Xianyang small semi-automatic terminal machine

-

2021-07-23 15:21:28Silent terminal machine non-normal stop causes

-

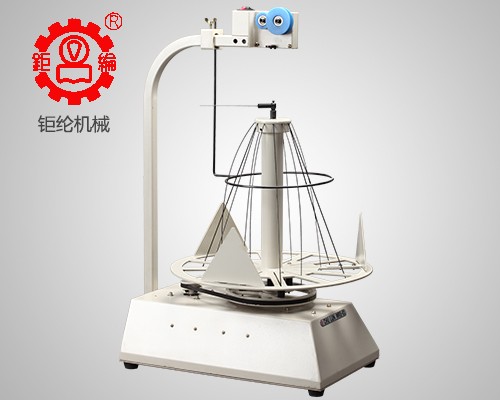

WRS-03 Restore Type Wire Discharge Machine

-

C1-3.0A Terminal Machine

-

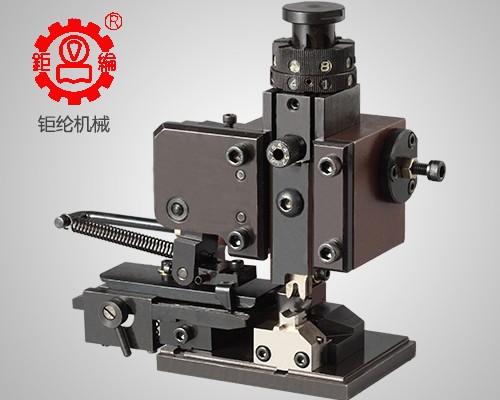

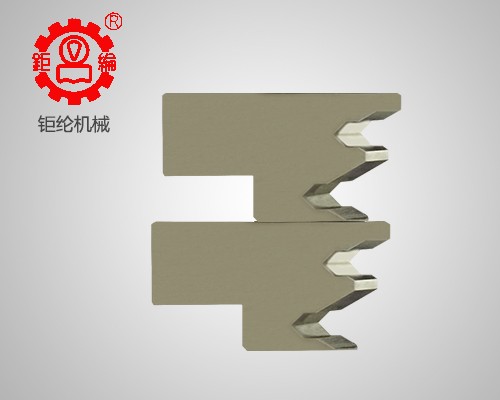

CLM-4E card die

-

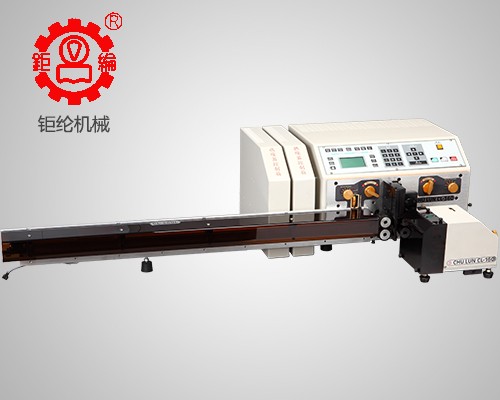

CL-950N Super Speed Automatic Computerized Wire Cutting Machine

-

CL-FSH Hanging pressure detector

-

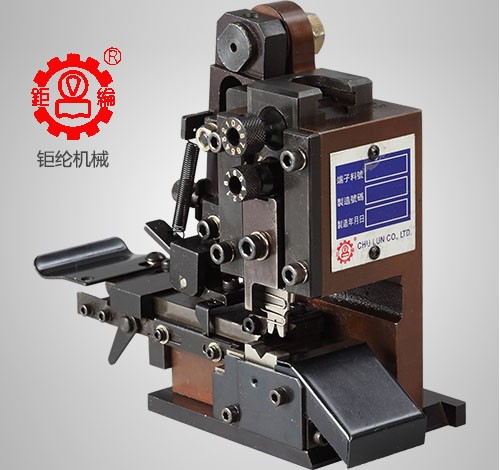

CLT-C2S with stripping and beating terminal machine

-

C3-2.5S High-speed stripping and pressing machine

-

Special cutting knives

EN

EN

CN

CN

QQ customer service

QQ customer service